HOW TO REPLACE CONNECTORS:

UNSEALED CONNECTORS -

In the Below article, we go through a step by step guide on replacing worn, broken or damaged unsealed connectors. This information applies to all unsealed LS connectors which can be purchased from our shop HERE

- Before you begin, ensure the new connector is the correct part. Inspect them side by side and if necessary, insert the unpinned new connector in the intended sensor. Most connectors will have Letters or Numbers marking each cavity, beginning with “A” or "1", cut the old connector and prepare to crimp on the new terminal. Crimping and pinning these connectors one by one avoids any confusion and incorrect pinning. OBD2 connects as shown here are UNIVERSAL between all brands and you should find the relevant pinout for your ECU before proceeding.

- Once cut, strip approx 3mm of insulation from the wire to reveal the conductor strands.

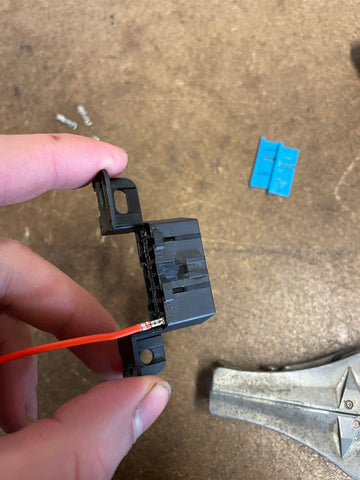

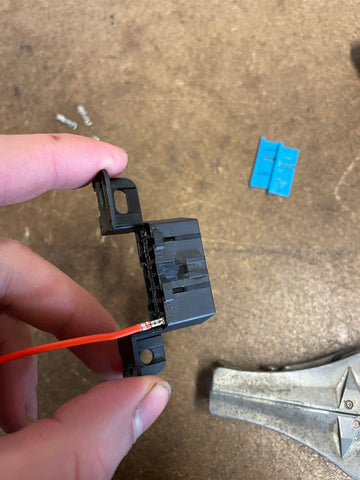

Insert the wire into the new terminal ensuring the copper strands are inline with the smaller crimp area and the insulation lines up with the larger crimp area.

- using the correct crimping tool firmly crimp the terminal firstly onto the copper conductor stands using the appropriate die, then changing the die used and crimping firmly the insulation. The end result should look like the below image . Holding the connector from the mating end, lightly tug the wire to ensure the crimp sufficiently holds the connector to the wire.

- Insert the terminal gently into the same marked cavity on the new connector. DO NOT USE EXCESSIVE FORCE. If the Terminal does not want to seat, change the orientation and try again. You should feel and hear a slight click when the terminal is locked in.

- Repeat the above steps for the remaining wires, one by one. Once all cavities are occupied (If required), clip on the TPA (Terminal Position Assurance) Lock to the rear of the connector. Compare the new connector to the old and that the colours match the removed connector.

- If you make a mistake, these terminals can be removed with speciality de pinning tools OR in most cases, with some welding wire and some patience. Please note, this technique applies to ALL connectors of this family, not just the connector pictured.

Use left/right arrows to navigate the slideshow or swipe left/right if using a mobile device

Hi.

I want to purchase the OBD2 connector kit but cannot find the information i need to connect it to the Aussie LS1 pdm / ecu. Can you help?

Hi.

I want to purchase the OBD2 connector kit but im struggling to find the correct pinout details to suit the Aussie LS1 pdm/ecu. I see pin 58 yellow for ob2 but not the other wires. Can you help please?

Thanks for your efforts information and products.